Ball Valve

The ball valve has a spherical plug as a closure member. Seal on ball valves is excellent, the ball contact circumferentially uniform the seat, which is usually made of soft materials.

Ball valves are mostly used in shutoff applications. They are not recommended to be used in a partially open position for a long time under conditions of a high pressure drop across the valve, thus the soft seat could tend to flow through the orifice and block the valve movement.

Depending on the type of body the ball valve can be more or less easily maintained. Drop pressure relative its hole size is low.

The seat material resistance of the ball valve limits the working temperature and pressure of the valve. The seat is plastic or metal made.

They are used in steam, water, oil, gas, air, corrosive fluids, and can also handle slurries and dusty dry fluids. Abrasive and fibrous materials can damage the seats and the ball surface.

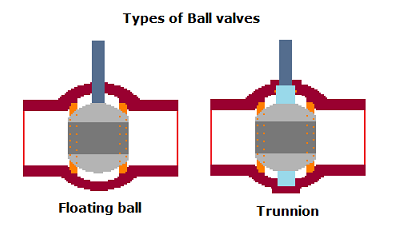

Types of ball valve:

-Float ball valve: the ball is held on two seat rings.

-Trunnion ball valve: the ball is supported on its vertical rotation axis by a trunnion. The trunnion absorbs the pressure from the flow, therefore the contact between the ball and the seat is not excessively stressed and the operating torque can remain low. This design is recommend for big diameters and high pressure.Optional locking device

ارتباط با ما

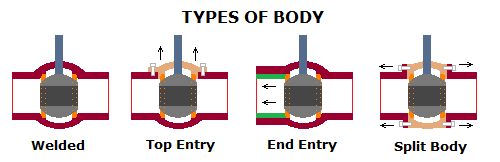

Split body: there are two or three pieces. It allows easy inspection and maintenance of all internal parts.

End entry: The body is one piece. The ball is entered from the axial entry.

Top entry: The ball can be taken out removing the top cover. It can be repaired on site.

Welded: Welded ball valves guarantee the absence of leakages along all the valve’s life, with no requirement for maintenance operations. This is a highly important requisite especially for ball valves installed onto underground and submarine pipelines. It is also often chosen for hazardous fluids.

Design Features

Full port or reduced port

Floating ball design

Blowout-proof stem

Casting or forging body

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Products Range

Size: 1/2″ ~ 56″ (DN15 ~ DN1400)

Rating: ANSI 150lb, 300lb, 600lb

Body Materials: Carbon Steel, Stainless Steel, Alloy Steel

Trim: A105+ENP, 13Cr, F304, F316

Operation: Lever, Gear, Electric, Pneumatic, Hydraulic

Applicable Standard

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598